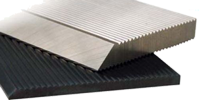

Corrugated Knife Stock

- Black Nitride

- Carbide Inlay

- D2-HCHC

- Euro-Lock Style (Carbide)

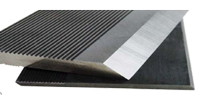

- Filler Wedge

- Knife-Lock (Carbide)

- M2-HSS

- T1-HSS

- V2-HSS

- V2-HSS+RW

- V3-HSS

Search

Black Nitride High Speed Steel: BN-HSS is our premium HSS with case hardened (carbon nitride0 and black oxide to resist pitch build up. BN-HSS offers up to 100% tool life increase over standard M2HSS, without being harder to profile shape. It features a long wearing cutting edge .010" deep that is more that 72 Rockwell C hardness. Great for long runs and stubborn hardwoods.

Euro-Lock knives are another high precision carbide system compatible with existing Wisconsin Knife or Leitz Style steel backing plates. Carbide knives offer the hardest metal available and more than 1,000% longer run than M2-HSS. Carbide is normally used for problem hardwoods (Teak, Maple, Hickory...) or engineered woods like MDF, LVL, edge glued stock, and glue bonded fiberboards. Carbide is roughly 89+ Rockwell C hardness and must be ground with diamond or silicon carbide grinding wheels.

High Speed Steel: Our true grade M2+HSS (AISI) steel offers 25%longer run times than D2HCHC grade. M2-HSS offers high levels of Tungsten (6% W), Molybdenum (5.5% Mo) and Vanadium (2.2% V). Its Rockwell hardness of 63 Rc offers better wear resistance in harder woods. Great for long runs in most soft and hardwoods.

T1 (AISI) steel offers 25% longer run times than M2+HSS. It is popular common European grade made of 18% Tungsten (W) for extra long runs and better resistance to abrasive glue lines. T1-HSS is 1 point harder (64 Rc) for extended tool life, yet easy to cut and profile grind because of the high levels of tungsten. It is popular for mills that run mostly hardwoods or for softwood mills that want the ultimate in knife life and cutting performance.

Coated V2-HSS is the ultimate value and long tool life. By applying the hard long wearing diamond dust chrome coating to the face of v2-HSS, the wear life can increase up to 100% at a small additional cost. The RW coating offers 72 Rc hardness to the cutting edge without increasing grind time. The RW coating is proprietary electro-plating process that adds .001" thick chip resistant coating. This steel is great for most hardwoods and can triple tool life in wet woods that contain tannic acid (oak, cedar and redwood).

V3-HSS offers up to 100% longer tool life over M2-HSS. This super alloy steel is great for long runs or on tough hardwoods. It is like M42 / T15-HSS and wears longer than M3-HSS. V3-HSS contains high levels of Vanadium, Tungsten, Molly, and Chromium for extended wear life due to the 66 Rockwell C hardness. This is the last step before going to carbide.