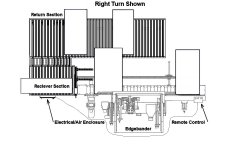

Thomas Turnbak Conveyor

Standard Features

- Powered Infeed Arms for Positive control of Parts

- Automatic 90* Turn of Rectangular Parts--No optional attachment needed

- Optional--Automatic Turner for Heavy Parts

- Two-Inch Roller Spacing--Return small parts without additional attachment

- Teflon-Lined steel Slides--Move parts easily and are durable

- Frictionless Heavy parts Transfer--for non-typical heavy parts (OPTIONAL)

- Variable-Speed Rollers--Roller speed can match speed of processing machine

- Portable Remote Control--puts control of the conveyor at the operators fingertips

- Steel Rollers with PVC Sleeve --For Stability & Strength

Standard Specifications:

- Roller Drive System Reliable Max Drive system powers rollers from underneath

- PLC Controlled

- Two-Inch roller spacing for small parts

- Remote Control and Variable Speed Drive (0-120FPM)

- Ten Urethane transfer belts (on 60" unit)

- Steel Rollers with PVC Sleeve

- Powered Infeed Arms

- Teflon-Lined steel transfer slides on receiver

- Adjustable height from 32" to 42" without casters; and 36" to 45" with casters

- Heavy-Duty Frame--2" welded square tubing with adjustable jack legs

- Power Requirements - 440/460/480 Volts, 3-Phase, 6-Amps; 208/220/230 Volts, 3-Phase, 10 Amps

- 1HP or 2HP (Depends on conveyor size and part sizes)

- Air Requirements - 60lbs @ 10cfm

Options:

- Urethane-Sleeved Rollers

- Casters

- Programmable Logic Controller--For seamless integration of processing machine & conveyor

- Ball Transfer

- Expandable Bridge

Options for Heavy Parts:

- Low Friction Heavy Parts Transfer

- Automatic Turner for Heavy Parts

Machine Operation:

(1) Photo eye detects the trailing edge of parts coming from a machine. This causes the receiver rollers to lower.

(2) Urethane belts move parts from the receiver section to the return.

(3) After the part leaves the receiver section, the rollers raise and the cycle is repeated

(1) Photo eye detects the trailing edge of parts coming from a machine. This causes the receiver rollers to lower.

(2) Urethane belts move parts from the receiver section to the return.

(3) After the part leaves the receiver section, the rollers raise and the cycle is repeated

For more information on this product please contact Joe Hall at (503) 869-2485 or

info@hall-man.com.

info@hall-man.com.