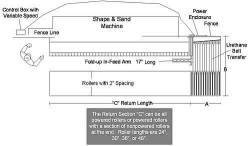

Thomas Paybak Conveyor

Standard Features

- Urethane Roller and Infeed Arm

- Torque Clutch-Controlled Speed Operation

- MaxDrive System

- Receive Butt-fed Parts

- Automatic 90* Turn of Rectangular Parts--No optional attachment needed

- Two-Inch Roller Spacing--Return small parts without additional attachment

- Teflon-Lined Steel Slides--Move parts easily and are durable

- Variable-Speed Rollers--Roller speed can match speed of processing machine

- Portable Remote Control--Move as needed

- Steel Rollers with PVC Sleeves --For Stability & Strength

Specifications:

- Pneumatic Clutch to mimic speed of processing machine as parts are received onto the conveyor.

- Remote control and Variable Speed Drive (0-120FPM)

- Max Drive -- Powered rollers driven from underneath by a series of pulleys and belts

- Two-inch roller spacing for small parts

- Steel Rollers with PVC Sleeve

- One Infeed Arm

- Urethane Transfer Belts

- Teflon-Lined Steel Slides on receiver

- Adjustable Height from 32" to 42" without casters; and 36" to 45" with casters

- Frame--Heavy-duty 2" welded square tubing with adjustable jack legs

- Horsepower--1HP or 2HP (Motor size is determined by various factors)

- Air Requirements--60lbs. @ 10 CFM

Options:

Pass-thru Switch

Casters

Programmable Logic Controller for seamless integration of processing machine and conveyor

Pass-thru Switch

Casters

Programmable Logic Controller for seamless integration of processing machine and conveyor

Machine Operation:

(1) A feed roller and a powered arm guide parts onto the receiver.

(2) A slip clutch matches processing speed then accelerates parts on the conveyor.

(3) Urethane belts move the parts from the receiver section to the return section.

(4) Parts may be butt-fed, since the process is continuous.

(1) A feed roller and a powered arm guide parts onto the receiver.

(2) A slip clutch matches processing speed then accelerates parts on the conveyor.

(3) Urethane belts move the parts from the receiver section to the return section.

(4) Parts may be butt-fed, since the process is continuous.

For more information on this product please contact Joe Hall at (503) 869-2485 or

info@hall-man.com.

info@hall-man.com.