Thomas Cutbak Conveyor

Standard Features

- PLC Control

- Teflon-Lined Steel Slides--Move parts easily and are durable

- Variable-Speed Rollers--Roller speed can match speed of processing machine

- Portable Remote Control--Move as needed

- Swing-out Section with Lockable Casters--Quick access to processing machine

Standard Specifications:

Optional:

110V/1PH Drives (1 & 2 HP)

Custom Sizes and Configurations

2-1/2" Dia. Steel Rollers

2HP Drive fro Larger Units

- MaxDrive--No welded bands on rollers

- InFeed Roller

- Variable-Speed Drive

- Rollers--2" Dia. PVC

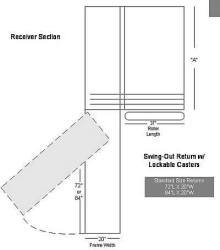

- Roller lengths--Receiver 37"L; Return 17"L

- Photoelectric Sensor

- 1/2" Dia. Hollow Urethane Transfer Belts

- Teflon-lined Steel Slides

- Remote Control--Standard Operators: START-STOP-SPEED

- PLC--Controlled

- Hinged Swing-Out Return, or Pinned Roll-Away

- 32"-42" Standard Height; Receiver-Adjustable legs/ Return-Lockable Casters

- Voltage & amp Requirements: 230V/3Ph-10 amps 460V/3Ph-6 amps

- 1HP Motor & Drive

- Air Requirement: 60lbs @ 10CFM

Optional:

110V/1PH Drives (1 & 2 HP)

Custom Sizes and Configurations

2-1/2" Dia. Steel Rollers

2HP Drive fro Larger Units

Machine Operation:

(1) Photo eye detects the trailing edge of parts coming from a machine. This causes the receiver rollers to lower

(2) Urethane belts move the parts sideways to the return section.

(3) After the part leaves the receiver section, the rollers raise and the cycle is repeated.

(1) Photo eye detects the trailing edge of parts coming from a machine. This causes the receiver rollers to lower

(2) Urethane belts move the parts sideways to the return section.

(3) After the part leaves the receiver section, the rollers raise and the cycle is repeated.

For more information on this product please contact Joe Hall at (503) 869-2485 or

info@hall-man.com.

info@hall-man.com.