Thomas Comebak Conveyor

Standard Features

- MaxDrive System--for a lifetime of low maintenance operation (NO RUBBERBANDS TO WELD!)

- Urethane Infeed Roller--to ensure total part acceptance

- Torque-Sensing Clutch--to exactly match the speed of your processing machine

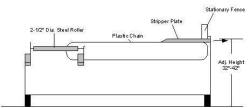

- Acetal (Plastic) Chain--for low impact, long life lateral part transfer

- Variable Speed--instantaneous speed adjustment at the operators fingertips

- Variable-Speed Rollers--roller speed can match speed of processing machine

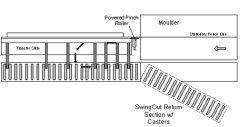

- Swing-Out Return--for easy access to your processing machine for maintenance or adjustments

Standard Specifications:

- Roller Lengths--Return 17"L

- MaxDrive System--No welded bands on rollers

- Infeed Roller

- 1HP 3 Phase Variable-Speed Drive

- Steel rollers

- Photoelectric Sensor

- Plastic Chain for Lateral Parts Transfer from Receiver to Return Section

- Remote Control--Standard Operations: START-STOP-SPEED

- Hinged Swing-Out Return or Pinned Roll-Away

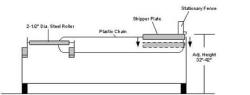

- 32"-42" Standard Height; Receiver-Adjustable Legs/ Return-Lockable Casters

- Voltage & Amp Requirements: 230V/3PH--10 amps 460V/3PH--6 amps

Options:

110V/1Ph Motor & Controls

2HP on Larger Units

110V/1Ph Motor & Controls

2HP on Larger Units

Machine Operation:

(1) A feed roller guides parts onto the receiver.

(2) (SP) Stripper Plate is retracted under fence, or (TR) Receiver roller bed is lowered under chain transfer level.

(3) The process is continuous, so parts may be butt-fed!

(1) A feed roller guides parts onto the receiver.

(2) (SP) Stripper Plate is retracted under fence, or (TR) Receiver roller bed is lowered under chain transfer level.

(3) The process is continuous, so parts may be butt-fed!

For more information on this product please contact Joe Hall at (503) 869-2485 or

info@hall-man.com.

info@hall-man.com.